High Corrosion Resistance Stainless Steel D Shackles with Saftey Pin

Product Features

- Manufactured from Stainless Steel EN10088 1.4404 (Marine Grade 316L)

- Excellent for lifting applications where a high level of corrosion resistance is required

- Factor of Safety 6:1

- Available with 2 pin types - E Type Safety Pin with Standard Nut (E Type) or Nylok Nut (E Type-NY)

- Special design of bolt ensures the nut is positioned correctly allowing sufficient room for the cotter pin

Quality Features

- Every shackle is proof tested to 2 x WLL and certified at our manufacturing facility in the North East of England

- All shackles are manufactured in accordance with the Machine Directive 2006/42/EC

- Inspection certificate BS EN 10204 3.1 available on request

- High quality finish and excellent polish

- Manufactured using the latest technology in electrical upset forging

Typical Applications

- Water utility installations & other corrosive facilities

- Pump chains and pump lifting

- Chemical installations - Chlorine plants etc

- General lifting in off-shore applications

- General lifting and tethering in leisure marine applications General lifting purposes

- General lifting purposes

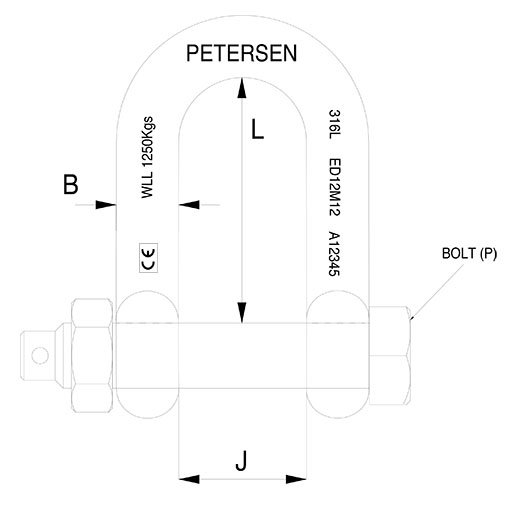

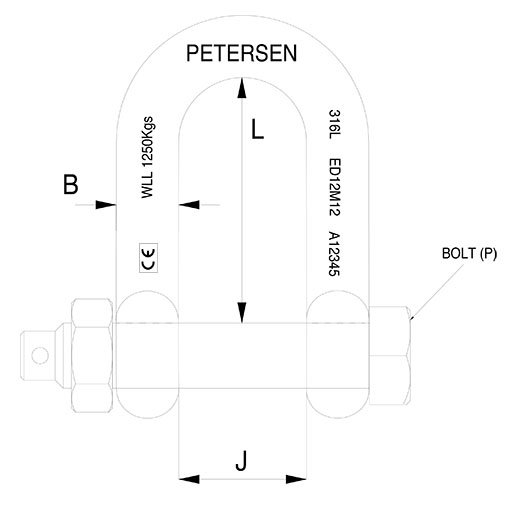

| Dimensions & WLL |

Pin Styles & Product Numbers |

Nominal Weight (g) |

| WLL (kg) |

Bolt Size |

B (mm) |

J (mm) |

L (mm) |

E Type |

E Type c/w Nylok |

| 350 |

M6 |

6.0 |

13.0 |

25.0 |

ED6M6 |

ED6M6-NY |

48 |

| 500 |

M8 |

8.0 |

16.0 |

32.0 |

ED8M8 |

ED8M8-NY |

75 |

| 800 |

M10 |

9.5 |

19.0 |

38.0 |

ED10M10 |

ED10M10-NY |

136 |

| 1000 |

M12 |

11.0 |

22.0 |

44.0 |

ED11M12 |

ED11M12-NY |

212 |

| 1250 |

M12 |

12.7 |

26.0 |

52.0 |

ED12M12 |

ED12M12-NY |

331 |

| 1800 |

M16 |

14.3 |

29.0 |

58.0 |

ED14M16 |

ED14M16-NY |

585 |

| 2800 |

M20 |

16.0 |

32.0 |

64.0 |

ED16M20 |

ED16M20-NY |

760 |

| 3300 |

M22 |

19.0 |

38.0 |

76.0 |

ED19M22 |

ED19M22-NY |

1180 |

| 4500 |

M24 |

22.0 |

44.0 |

88.0 |

ED22M24 |

ED22M24-NY |

1750 |

| 5000 |

M27 |

25.4 |

50.0 |

100.0 |

ED25M27 |

ED25M27-NY |

2600 |

<< Back to Stainless Steel Lifting Shackles

Petersen Stainless Rigging Ltd

Petersen Stainless Rigging Ltd